HEAT nổ rồi mới xuyên nhá, có điều xuyên bằng dòng kim loại nóng chảy nên sau khi xuyên sẽ gây cháy nổ

@panzerkelin :Second World War

British naval 15-inch capped armor-piercing shell, 1943During WWII, projectiles used highly alloyed steels containing nickel-chromium-molybdenum, although in Germany, this had to be changed to a silicon-manganese-chromium-based alloy when those grades became scarce. The latter alloy, although able to be hardened to the same level, was more brittle and had a tendency to shatter on striking highly sloped armor. The shattered shot lowered penetration, or resulted in total penetration failure; for armor-piercing high-explosive (APHE) projectiles, this could result in premature detonation of the HE filling. Highly advanced and precise methods of differentially hardening the projectile were developed during this period, especially by the German armament industry. The resulting projectiles gradually change from high hardness (low toughness) at the head to high toughness (low hardness) at the rear and were much less likely to fail on impact.

APHE shells for tank guns, although used by most forces of this period, were not used by the British

http://en.wikipedia.org/wiki/Armor-piercing_shot_and_shell

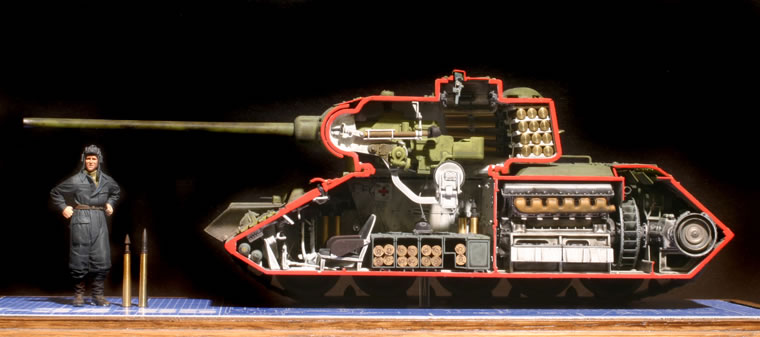

. Chỉ toàn bị bắn thủng rồi bốc cháy, lúc đó crew chui ra khỏi tank và tìm nơi nấp, chỉ có một trường hợp lính lái T-34 có thằng sĩ quan bị thương vì khi bị trúng đạn, dù không bị xuyên nhưng lớp vỏ trong của T-34 đúc kém nên văng ra làm thương tay chỉ huy

. Chỉ toàn bị bắn thủng rồi bốc cháy, lúc đó crew chui ra khỏi tank và tìm nơi nấp, chỉ có một trường hợp lính lái T-34 có thằng sĩ quan bị thương vì khi bị trúng đạn, dù không bị xuyên nhưng lớp vỏ trong của T-34 đúc kém nên văng ra làm thương tay chỉ huy  .

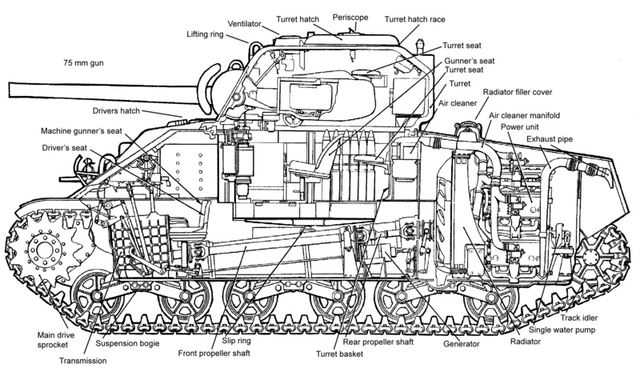

. vấn đề là trong xe tăng thì khoang lái xe với khoang chỉ huy có thông nhau, nhưng vẫn được ngăn cách tương đối bằng một vách mỏng nên khi xe bị bắn từ đằng trước thì lái xe chết, bộ truyền động hỏng, mảnh đạn văng ra nêu xuyên qua vách thép cũng bị giảm động năng nhiều, không còn đủ gây chết người ngồi ở khoang chiến đấu, đồng thời hệ truyền động của xe cũng hư luôn nên người còn sống chạy luôn khỏi xe.

vấn đề là trong xe tăng thì khoang lái xe với khoang chỉ huy có thông nhau, nhưng vẫn được ngăn cách tương đối bằng một vách mỏng nên khi xe bị bắn từ đằng trước thì lái xe chết, bộ truyền động hỏng, mảnh đạn văng ra nêu xuyên qua vách thép cũng bị giảm động năng nhiều, không còn đủ gây chết người ngồi ở khoang chiến đấu, đồng thời hệ truyền động của xe cũng hư luôn nên người còn sống chạy luôn khỏi xe. .

.